TiO2 Deposited Algae Cellulose Sheet for Antimicrobial Membrane

Priyank L Bhutiya*, M Abdul Rasheed, P L S Rao and S Zaheer Hasan

Department of Petroleum Research, Gujarat Energy Research and Management Institute, Gandhinagar, India

- *Corresponding Author:

- Priyank L Bhutiya

Department of Petroleum Research,

Gujarat Energy Research and Management Institute, Gandhinagar,

India,

E-mail: bhutiyapriyank@gmail.com

Received date: February 15, 2023, Manuscript No. IPNTO-23-15917; Editor assigned date: February 17, 2023, PreQC No. IPNTO-23-15917 (PQ); Reviewed date: February 27, 2023, QC No. IPNTO-23-15917; Revised date: March 08, 2023, Manuscript No. IPNTO-23-15917 (R); Published date: March 17, 2023, DOI: 10.36648/2471-9838.9.2.118

Citation: Bhutiya PL, Rasheed MA, Rao PLS, Hasan SZ (2023) TiO2 Deposited Algae Cellulose Sheet for Antimicrobial Membrane. Nano Res Appl Vol. 9 No.2:118

Abstract

Bird’s nested type of architectural structure of cellulose nanofibers (Iα) was extracted from marine green seaweed Chaetomorpha antennina by using simple sodium chlorite without using any harsh treatment such as acidic, mechanical or enzymatic treatment which has been widely used in commercial. Further, Titanium Oxide (TiO2) nanoparticles were grown over the seaweed cellulose porous sheet by using single step hydrothermal method. These TiO2 nanoparticles deposited cellulose sheet were characterized by FT-IR, XRD, TGA and SEM. TiO2 deposited cellulose sheet gave very good antibacterial activity towards gram-positive (Staphylococcus aureus) and gram-negative (Escherichia coli) microbes. TiO2 deposited cellulose sheet have great potential in waste water treatment, packaging, textile and pharmaceutical applications.

https://sporbahisleri.livejournal.com https://wakelet.com/@SporBahisleri67459 https://theomnibuzz.com/author/sporbahisleri/ https://lessons.drawspace.com/profile/322207/sporbahisleri/workflow https://writeupcafe.com/profile/sporbahisleri/ http://www.pearltrees.com/sporbahisleri https://pharmahub.org/members/26874/blog https://www.zupyak.com/u/Spor-Bahisleri/ https://www.metroflog.co/sporbahisleri https://www.fuzia.com/fz/spor-bahisleri https://tr.pinterest.com/sporbahislerim/ https://my.getjealous.com/sporbahisleri https://sporbahisleri.contently.com https://hubpages.com/@sporbahisleri https://www.tumblr.com/sporbahisleri https://hub.docker.com/u/sporbahislerim https://betsiteleri.blogfree.net https://betsiteleri.amebaownd.com https://sporbahisleri.pixnet.net/blog https://betsiteleri.seesaa.net https://betsiteleri.threadless.com https://betsiteleri.neocities.org https://bahissiteleri.localinfo.jp https://betsiteleri.shopinfo.jp https://teletype.in/@betsiteleri https://ubl.xml.org/users/sporbahisleri https://betsiteleri.educatorpages.com https://betsiteleri.onlc.fr https://sporbahisleri.gumroad.com

Keywords

TiO2; Seaweed cellulose; Antibacterial; Pharmaceutical

Introduction

Over the past decade, seaweeds have become to focal point in world because of its potential application in different field such as pharma, cosmetics, wastewater and medical field. According to united nations data, world-wide seaweed production is 26 million tons per annum with market value USD 8.4 billion (FAO, 2014) [1]. Generally, algae are classified according to its colour which is present in its cell wall such as red, green, brown. The major advantage of algae that they grow very fast and can’t compete with land or agriculture product. It cannot requirement of any supplement such as fertilizer and one of the main parts that it cannot affect food chain. It is very cheap and also production cost is also low it can be cultivated in many parts of world especially, China, Europe and Indonesia [2]. But some other side if we see, the eutrophication of algae is a major issue in worldwide. It causes severe economy and environmental threats to tourism industry as well as aquaculture and also high investment require discarding this biomass in China. Therefore, finding a right application of algae which can be applicable in industries.

Macro algae derived polymer such as carrageenan, cellulose, alginate, fucoidan, agarose, pectin, xylan, ulvan and amylose which have high value added applications in industries. Among all, seaweed cellulose has drawn more attention due to its unique properties as compared to land sources cellulose. Generally, green seaweed have higher amount of nanofibers cellulose in their cell wall as compared to red and brown seaweed. Seaweed cellulose consists only D-glucose monomers which have X-ray diffraction pattern similar to cellulose I from land sources. Green seaweed Chaetomorpha antennina, normally up to 10 cm-20 cm tall and grows on submerged rocks. It also have filamentous erect and contain high amount of cellulose and other lower amount of components [3,4].

Cellulose have many important properties such as high surface area, high strength, high crystallinity, low density, low thermal expansion and biodegradability but it have not antimicrobial activity so cellulose deposited with metal oxide nanoparticles can be potential materials for antibacterial activity which can be used in medical and water treatment industries for antibacterial and antiviral membrane. Several metal oxide nanoparticles like gold, platinum, zinc, cuprous, titanium and silver which have good antibacterial activity and also non-toxic for human so it can be easily deposited over cellulose nanofibers for the development of antimicrobial membrane [5]. Among all, Titanium Oxide (TiO2) have an excellent properties like photocatalytic, strong oxidizing power, antimicrobial, antifouling and optical so it is used in cosmetics, paints, waste water treatment, pigments, capacitor, food packaging, medicine and solar cells. It is an environment friendly catalyst and nontoxic for human. TiO2 nanoparticles coated fibers were synthesized by various methods like sol-gel, hydrothermal, sputtering, crosslinking, plasma, hydrolysis and suspension [6].

In present study, we prepared antimicrobial titania nanoparticles based seaweed cellulose sheet which was environment friendly and also derived from renewable marine green seaweed Chaetomorpha antennina from coastal of Gujarat, India.

Materials and Methods

Materials

Sodium chlorite, sodium hydroxide and hydrochloric acid were purchased from Fisher Scientific, USA. Nutrient agar and nutrient broth were purchased from Merck Laboratories, India. Ethanol (99.9% pure) and titania powder were purchased from SRL, India. All reagents were analytical grade and used without any further purification. Seaweed Chaetomorpha antennina, was collected from Porbandar, Gujarat, India. The bacterial strains were acquired from GERMI, Gandhinagar.

Preparation of TiO2 nanoparticles on seaweed cellulose

Cellulose was extracted from algae by using simple bleaching agent as reported by [3]. Hydrothermal method was used to grow TiO2 nanoparticles on seaweed cellulose. 0.2 g of TiO2 powder was mixed in solution of 5 mL ethanol and 5 mL of 5 M sodium hydroxide. Further, it was stirred for 50 min after strring, 1.0 g of dried seaweed cellulose powder with 50 mL of distilled water was added and again it was stirred for 30 min. Then, it was transferred into 100 mL Teflon lined autoclave and heated to 180°C for 18 h. Then, it was cooled down at room temperature and filtered. Then solid residue was washed with 0.1 N HCL, ethanol and hot water. Then the dispersion was filtered by nylon filter membrane (0.4 μm, Whatman) under vacuum filtration. Hand press method to make flat surface of prepared sheet. Then it was dried at 50°C [6].

Characterization

TiO2 nanoparticles deposited seaweed nanofibrous cellulose sheet was characterized by different analytical techniques such as X-Ray Diffraction (XRD), Fourier Transform Infrared spectra (FT-IR), Field Emission Scanning Electron Microscope (FE-SEM) and Energy Dispersive X-ray spectroscopy (EDX), Thermo Gravimetric Analysis (TGA).

Powdered XRD patterns were carried out on an Xpert Pro Xdiffractometer (PANalytical) using Cu-Kα radiation at an accelerating voltage of 40 kV and current of 40 mA. All data were collected between 10°C to 80°C.

The FT-IR spectrum was obtained using FT-IR spectrophotometer (PerkinElmer, Spectrum 2), in the range of 400-4000 cm-1 using ATR mode of operation.

The surface morphology was characterized by FE-SEM (JSM-7600F, JEOL). For FE-SEM, sample was placed over carbon tape on a 1 cm diameter and supper coated with Pt for prior for imaging. The images were taken 5.0 KV acceleration voltages, using lens detector. An elemental observation was carried out by energy dispersive X-ray spectroscopy (Oxford, X-max).

Thermal stabilities were analyzed by thermo gravimetric analyzer (Mettler Toledo, TGA/DSC-1) from room temperature to 800°C at a heating rate of 10°C min-1 under nitrogen atmosphere.

Antibacterial test have been performed as reported by [6].

Result and Discussion

FT-IR analysis

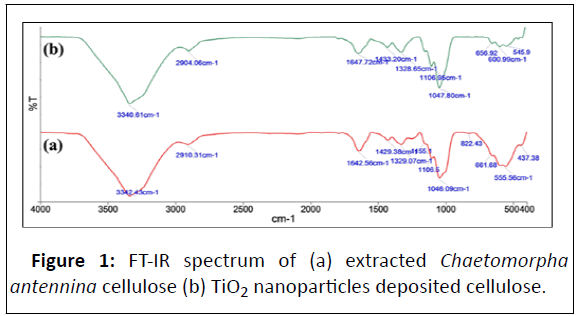

In Figure 1 (a,b) TiO2 nanoparticles peaks were observed between 500-600 cm-1. Generally, the peaks nearly at 600 cm-1 and 545 cm-1 were attributed to stretching vibration of Ti-O anatase phase [7]. The peaks shows at finger print regions in the case of TiO2 nanoparticles deposited cellulose become broadened. This might be due to overlapping of cellulose with titanium dioxide nanoparticles and also the peak intensity at 3340 cm-1 and 1647 cm-1 were decreased as compared to seaweed cellulose. This might be due to the interaction between - OH groups of seaweed cellulose and titanium ions occurred which decreased the -OH groups in cellulose so it decreases the intensity [6].

XRD analysis

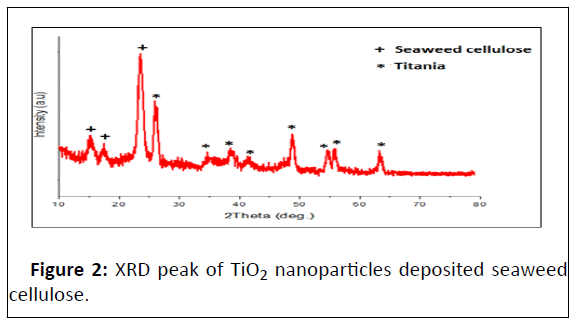

Figure 2 showed that the XRD patterns of Titanium Oxide nanoparticles (TiO2) deposited algae cellulose sheet which showed peaks at 2θ value of 25.91°, 36.1°, 37.8°, 41.2°, 50.2°, 54.1°, 55.4°, 63.02° and its diffraction planes are (110), (103), (004), (112), (200), (105), (211) and (204), respectively. These all XRD peaks were very well matched with JCPDS file no. 21-1272. From the XRD peaks, there have mainly anatase phase of TiO2 was formed over algae surface [8]. The Crystallinity Index (CI) of algae celluloseand TiO2 nanoparticles deposited cellulose were 85% and 70.02%, respectively which indicated that the crystalline structure of seaweed cellulose was slight destroyed by TiO2 nanoparticles and also crystallite size of TiO2 nanopar - ticles was 72 nm.

TGA analysis

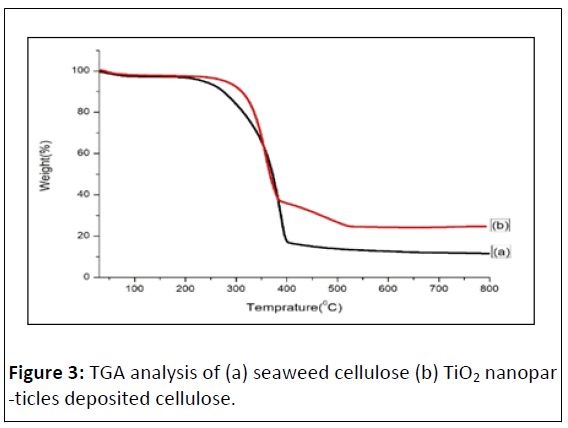

TGA analysis of algae cellulose and TiO2 nanoparticles deposited cellulose showed in Figure 3 (a,b) respectively. The weight loss started around 100°C due to moisture loss. The main degradation of algae cellulose was observed at 200°C to 380°C. In this stage, the total mass loss of seaweed cellulose and TiO2 nanoparticles deposited cellulose were 75.09% and 62.42%, respectively. The total weight loss of seaweed cellulose and TiO2 nanoparticles deposited cellulose were 88.43% and 80.02%, respectively. This indicated that the TiO2 nanoparticles deposited cellulose have more stable due to its catalytic properties [9].

SEM and EDX analysis

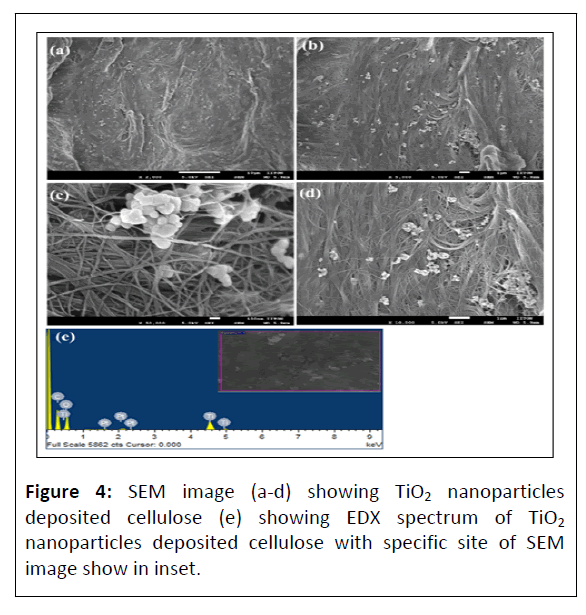

Figure 4 (a-d) showed that the SEM images of TiO2 nanoparticles deposited algae cellulose. Generally, the formation of TiO2 nanoparticles over cellulose due to the interaction between hydroxyl groups over cellulose and titanium ions by electrostatic interactions. As the hydrothermal reaction proceeds, nuclei were formed on the surface of seaweed cellulose and then TiO2 nanoparticles were formed via growth process. Figure 4 (c and d) showed that the agglomeration of TiO2 nanoparticles was formed. This could be minimized by addition of external reducing agents such as citric acid [7]. From the SEM images, the average diameter of TiO2 nanoparticles was around 80 nm. Figure 4 (e) showed that the EDX spectrum of TiO2 nanoparticles deposited cellulose at the selected site of SEM image which shows in inset. It show that the presence of carbon, oxygen, platinum and titanium were 49.67%, 44.08%, 0.19% and 6.05%, respectively. Platinum (Pt) peaks were due to sputter coated of sample with Pt for prior for imaging which can be minimized.

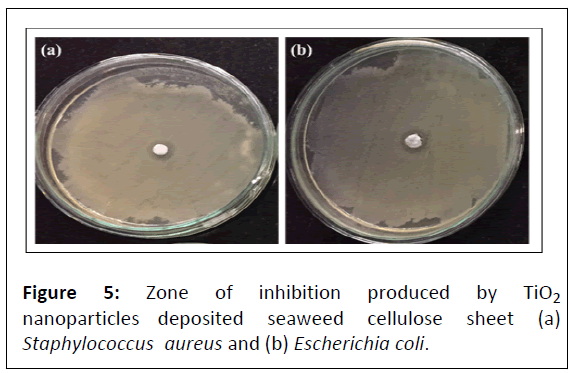

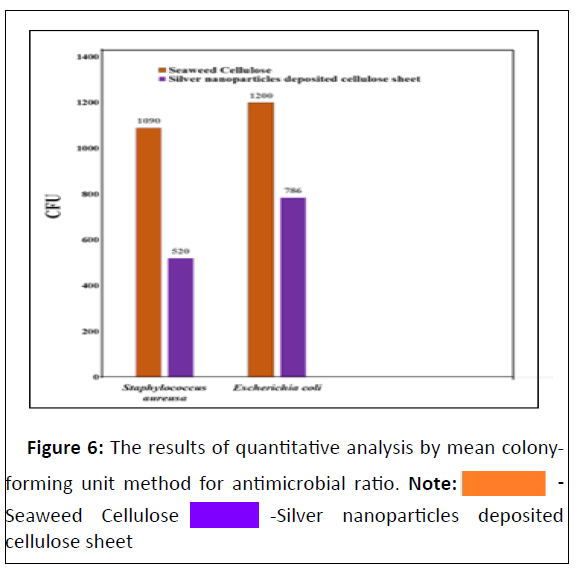

Antibacterial activity

Figure 5 shows that the maximum zone of inhibition of TiO2 nanoparticles deposited algae cellulose sheet against gram positive (Staphylococcus aureus was 28 mm) and gram negative (Escherichia coli was 21 mm) microbes by disk diffusion method. Figure 6 shows that the antimicrobial ratio by using mean colony forming unit method and it was noted for gram positive (Staphylococcus aureus was 97.8%) and gram negative (Escherichia coli was 96.4%) microbes. The antimicrobial activity of TiO2 nanoparticles deposited cellulose sheet was due to positive charge of TiO2 and negative charge of microorganism thus leads to oxidation reaction in cell membrane and it damage enzymes and DNA, thus leads to bacterial death [10].

Conclusion

TiO2 deposited cellulose sheet was prepared by using simple bleaching process and one of the important things that it is totally biodegradable because it was made from filamentous green seaweed so it have potential industrial applications in food, packaging, pharmaceutical, waste water treatment etc. This have high commercial potential in future so it can generate economy which called as blue economy for coastal people because cultivation of seaweed to manufacturing membrane have tremendous source of income for eco-friendly product manufacturing.

Competing Interests

The authors declare that they have no competing interest.

Funding

This work was carried out independently without any funding agencies.

Acknowledgement

Authors acknowledged to Mr. L Bhutiya, Porbandar for helping collection of seaweed from under the sea.

References

- FAO (2014) The state of world fisheries and aquaculture: Opportunities and challenges. Rome: 209.

- Trivedi N, Baghel RS, Bothwell J, Gupta V, Reddy CRK (2016) An integrated process for the extraction of fuel and chemicals from marine macroalgal biomass. Sci Rep 6: 30728.

[Crossref], [Google Scholar], [Indexed]

- Bhutiya PL, Misra N, Rasheed MA, Hasan SZ (2018) Nested seaweed cellulose fiber deposited with cuprous oxide nanorods for antimicrobial activity. Int J Biol Macromol 117: 435-444.

[Crossref], [Google Scholar], [Indexed]

- Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem Soc Rev 40: 3941-3994.

[Crossref], [Google Scholar], [Indexed]

- Tian H, He J (2016) Cellulose as a scaffold for self-assembly: From basic research to real applications. Langmuir 32: 12269-12282.

[Crossref], [Google Scholar], [Indexed]

- Chauhan I, Mohanty P (2015) In situ decoration of TiO2 nanoparticles on the surface of cellulose fibers and study of their photocatalytic and antibacterial activities. Cellulose 22: 507-519.

[Crossref], [Google Scholar]

- Chauhan I, Chattopadhyay S, Mohanty P (2013) Fabrication of titania nanowires incorporated paper sheets and study of their optical properties. Materials Express 3: 343-349.

[Crossref], [Google Scholar]

- Jiao Y, Wan C, Li J (2017) Anatase TiO2/cellulose hybrid paper: Synthesis, characterizations and photocatalytic activity for degradation of indigo carmine dye. Functional Materials Letters, 10: 1750018.

[Crossref], [Google Scholar]

- Li SM, Dong YY, Ma MG, Fu LH, Sun RC, et al. (2013) Hydrothermal synthesis, characterization and bactericidal activities of hybrid from cellulose and TiO2. Carbohydr Polym 96: 15-20.

[Crossref], [Google Scholar], [Indexed]

- Senarathna ULNH, Fernando SSN, Gunasekara TDCP, Weerasekera MM, Hewageegana HGSP, et al. (2017) Enhanced antibacterial activity of TiO2 nanoparticle surface modified with Garcinia zeylanica extract. Chem Cent J 11: 7.

[Crossref], [Google Scholar], [Indexed]

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences

-Seaweed Cellulose

-Seaweed Cellulose  -Silver nanoparticles deposited cellulose sheet

-Silver nanoparticles deposited cellulose sheet